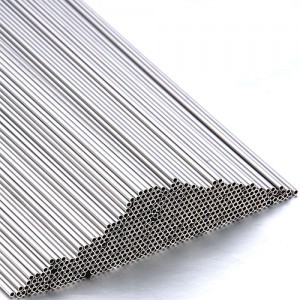

Kawat las nikel, ErNiCu-7, Kawat Las Monel 400/K500

Kawat las nikel, ErNiCu-7, Kawat Las Monel 400/K500,

AWS A5.14 ErNiCu7, Monel 400 / K500 Nikel Welding, kawat las nikel,

ErNicu-7 (Monel 400/K500) Kawat Las

♦Nama Bahan Pengelasan: Kawat las nikel, ErNiCu-7, Kawat Las Monel 400/K500

♦MOQ: 15kg

♦Formulir: MIG (15kgs/spool), TIG (5kgs/box)

♦Ukuran: 0.01mm-8.0mm

♦Ukuran Umum: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

♦Standar: Selaras karo Sertifikasi AWS A5.14 ASME SFA A5.14

Hubungi Kita kanggo Sinau Luwih!

ErNiCu-7 Material adhedhasar Monel 400 lan Monel K500, kabel welding iki utamané digunakake kanggo welding MONEL400 alloy, MONELR404 alloy lan MOENLK-500 alloy dening tungsten inert-gas welding, MGW lan submerged busur welding, lan uga bisa digunakake kanggo lumahing lumahing baja welding. dening MGW lan submerged busur welding.

Disaranake nggunakake tutup kabel nikel Erni-1 kanggo kondisi welding gas tartamtu.

Komposisi Kimia ERNiCu-7

| C | Al | Ni | Si | Mn | P | S | Fe | Cu | Ti | Liyane |

| ≤0.15 | ≤1.25 | 62.0-69.0 | ≤1.25 | ≤4.0 | ≤0.02 | ≤0,015 | ≤2.5 | Bal | 1.5-3.0 | ≤0,50 |

ERNiCu-7 Parameter Welding Khas

| Dhiameter | Proses | Volt | Ampere | Gas pelindung | |

| In | mm | ||||

| 0.035 | 0.9 | GMAW | 26-29 | 150-190 | 75% Argon + 25% Helium |

| 0.045 | 1.2 | GMAW | 28-32 | 180-220 | 75% Argon + 25% Helium |

| 1/16 | 1.6 | GMAW | 29-33 | 200-250 | 75% Argon + 25% Helium |

| 0.035 | 0.9 | GTAW | 12-15 | 60-90 | 100% Argon |

| 0.045 | 1.2 | GTAW | 13-16 | 80-110 | 100% Argon |

| 1/16 | 1.6 | GTAW | 14-18 | 90-130 | 100% Argon |

| 3/32 | 2.4 | GTAW | 15-20 | 120-175 | 100% Argon |

| 1/8 | 3.2 | GTAW | 15-20 | 150-220 | 100% Argon |

| 3/32 | 2.4 | SAW | 28-30 | 275-350 | Fluks sing cocog bisa digunakake |

| 1/8 | 3.2 | SAW | 29-32 | 350-450 | Fluks sing cocog bisa digunakake |

| 5/32 | 4.0 | SAW | 30-33 | 400-550 | Fluks sing cocog bisa digunakake |

ERNiCu-7 Sifat Mekanik

| kahanan | Kekuatan Tarik MPa (ksi) | Kekuwatan Hasil MPa (ksi) | Elongation% |

| AWS reauirement | 480(70) Biasane | Gak di jelasno | Gak di jelasno |

| Asil khas minangka gandheng | 530(77) | 360(53) | 34 |

Kenapa ERNiCu-7?

•Ora Preheat dibutuhake, suhu interpass maksimum 150 ℃ lan ora PwHT dibutuhake

•Aplikasi welding sing ora padha kalebu nggabungake paduan menyang Nikel 200 lan paduan tembaga-nikel-

•Digunakake kanthi akeh ing aplikasi segara amarga resistensi sing apik kanggo efek korosif saka banyu laut lan banyu payau.

•Bisa digunakake kanggo overlay MIG ing baja sawise lapisan pisanan karo nikel 208

MOQ: 15kg

Formulir: MIG (15kgs/spool), TIG (5kgs/box)

Ukuran: Diameter 0.01mm-8.0mm Ukuran Umum: 0.8MM/1.0MM/1.2MM/1.6MM/2.4MM/3.2MM/3.8MM/4.0MM/5.0MM

Standar: Selaras karo Sertifikasi AWS A5.14 ASME SFA A5.14