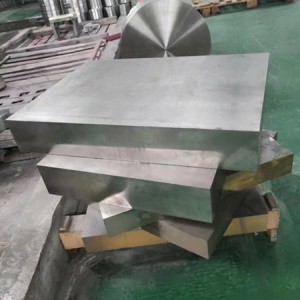

Pabrik produksi sumber mesh titanium.Titanium wire mesh, medis titanium mesh

Pabrik produksi sumber mesh titanium.Titanium wire mesh, medis titanium mesh,

kelas 2, kelas 5, Kelas 11.Kelas 12.Kelas 16, Kelas 23, Kelas 7, kelas 9, Gradel, TA2, TAl, TC4,

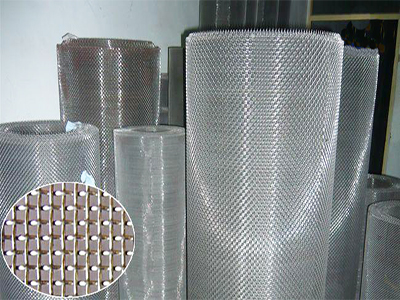

Titanium Mesh:Titanium Mesh digawe dening kabel Titanium Alloys, perusahaan kita gabung karo pabrik Mesh ngembangake macem-macem produk kanggo produk wire mesh lan produk sing luwih digawe.kita wis akeh taun pengalaman ing produksi kabel bolong, lan bolong titanium diprodhuksi nduweni karakteristik kinerja nyaring stabil lan nggoleki.

• Jinis:

→ Jaring tenun polos → Jaring tenun kepar

→ Jaring tenun pra-crimped → jala tenun Walanda

• Spesifikasi: 1 mesh-100 mesh

Standar ASTM dituruti ing produksi wire meshes.Spesifikasi bolong sing kasedhiya wiwit saka abot banget nganti apik banget.Bolong paling abot digawe saka kawat 8.0mm nalika bolong paling apik digawe saka kawat 0.03mm kanthi 360mesh / inci.

• Aplikasi:Titanium wire mesh bisa digunakake ing saringan tahan suhu dhuwur, gawe kapal, manufaktur militer, saringan kimia, saringan mekanik, jaring pelindung elektromagnetik, saringan desalinasi banyu laut, jaring perawatan panas tungku listrik suhu dhuwur, saringan lenga, pangolahan pangan, filtrasi medis.

| Titanium Alloys Material Jeneng Umum | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Komposisi Kimia Paduan Titanium ♦

| sasmita | Komposisi kimia, persen bobot (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur liyane Maks.saben | Unsur liyane Maks.gunggung | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12 0.25 | — | 0.12 0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12 0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04 0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦ Sifat Fisik Titanum Alloy ♦

| sasmita | Sifat fisik | |||||

| Kekuwatan tensile Min | kekuatan ngasilaken Min (0,2%, offset) | Elongation ing 4D Min (%) | Pengurangan Area Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

Titanium bolong utamané dipigunakaké kanggo asam, kahanan lingkungan alkali screening lan filtrasi utawa gas, filtrasi Cairan lan media liyane misahake.Ana papat cara nenun polos, twill nenun, wis crimp nenun lan Walanda weave.Saikang Metal Technology Co., Ltd Komitmen kanggo nyedhiyakake produk / layanan sing berkualitas kanggo pelanggan. Yen sampeyan kasengsem karo produk lan layanan, hubungi kita lan ngarepake balesan sampeyan.