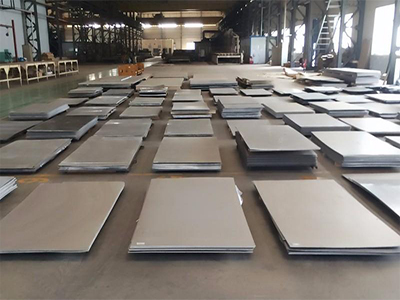

Lembaran lan Plat Titanium

• Bahan Lembaran Titanium: Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23

• Wangun: Forging Sheet, Cold Rolling Sheet, Hot Rolling Sheet

• Ukuran:Ketebalan: 0,3 ~ 5mm, Jembar: 400 ~ 3000mm, Dawane: ≤6000mm

• Ketentuan:Hot Forging & Hot Rolling, Cold Rolled, SolutionAnnealed

• Standar:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 etc

| Titanium Alloys Material Jeneng Umum | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20 Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15 Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Lembaran Titanium lan Plat Titanium:We utamané nyedhiyani sheet titanium murni saka Gr1, Gr2, Gr4 gelar;Kanggo titanium alloy sheet, We utamané nyedhiyani Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 lan gelar liyane, Lagi diprodhuksi ing basis saka piring titanium karo Rolling kadhemen luwih;proses produksi sheet titanium luwih rumit.Kontrol deformasi luwih strictly ing proses rolling.Sing bisa Cut ing ukuran beda miturut kabutuhan customer, nemen shorten wektu pangiriman.

♦ Komposisi kimia Lembaran Titanium ♦

| sasmita | Komposisi kimia, persen bobot (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur liyane Maks.saben | Unsur liyane Maks.gunggung | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12 0.25 | — | 0.12 0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12 0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04 0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | — | — | — | — | 0.1 | 0.1 |

♦Titanum Alloy SheetSifat fisik ♦

| sasmita | Sifat fisik | |||||||

| Kekuwatan tensile Min | kekuatan ngasilakenMin (0,2%, offset) | Elongation ing 4D Min (%) | Pengurangan Area Min (%) | Tes Bend (Radius Mandrel) | ||||

| ksi | MPa | ksi | MPa | <1,8 mm Ing kekandelan | 1.8-4.8mm Ing kekandelan | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |